DIY - Automated plants watering system: mounting

As we transition into the practical implementation of our Arduino-powered automatic watering system, the focus shifts from theory to the tangible. This section of the guide will meticulously guide you through the steps of physically mounting the components, integrating sensors, and establishing the necessary connections between modules. It's an opportunity to transform conceptual understanding into hands-on reality. Prepare to immerse yourself in the practical aspects of this project, where we navigate through the nuances of placing each module and executing the precise wiring required to bring your plants care system to life.

Automated plants watering project

DIY - Automated plants watering system: concept

DIY - Automated plants watering system: mounting

DIY - Automated plants watering system: code

DIY - Automated plants watering system

Components

| 1x Arduino Nano (or another Arduino module)

|

| 1x Mini-breadboard

|

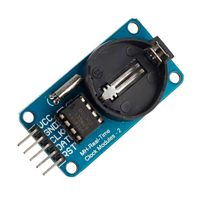

| 1x DS1302 module $1.14 |

| 1x CR2032 Battery

|

| 1x Water pump

|

| 1x Water pump pipes

|

| 1x Voltage regulator with 5V output (AMS1117) $1.60 |

| 1x Switch button

|

| 1x Push button $2.46 |

| 1x Potentiometer $2.32 |

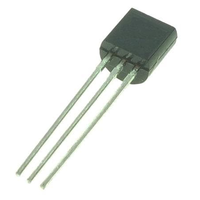

| PN2222A Transistor

|

| Resistors kit $3.43 |

| 2x LEDs

|

| 2x LED Holder Bezel

|

| 1x Barrel plug

|

| 9V Battery holder + 9V Battery $1.71 |

Prerequisites

We suggest reviewing articles that are either directly or indirectly referenced in this guide. This will provide you with a comprehensive understanding of each component and how they interact.

Water deposit

For our watering system, we will need a water container. Any common and standard items suitable for water storage can be used as a deposit. The larger the storage container, the less frequent the need for recharging.

We've selected the bottle shown on the image as our water reservoir. With a capacity of 1.5 liters, it should be sufficient for watering a medium-sized plant for several days.

For the water pump to effectively move water from the bottom of the bottle to the plant, it must be placed inside. To accomplish this, we place the pump inside the bottle, and then we pull out the wires. This involves creating a small opening at the base of the bottle solely for the wires, enabling us to thread them out and connect the pump to our plant care station. To conclude the process, we use waterproof silicone to seal the opening, ensuring there is no water loss.

On the opposite end, there will be a water pipe directly connecting to the plant to provide hydration.

Water pump wiring

To facilitate the connection of the pump wires with the main system, we've used a barrel plug. The junction between the pump wires and the connector wires is shielded by heat shrink wraps, providing effective insulation from external elements.

This approach ensures a secure and well-insulated connection, contributing to the overall reliability of the system.

Plants care station

The plants care station takes on the responsibility of processing available information, making decisions, and controlling the activation and deactivation of the watering system. Designed for both indoor and outdoor use, it hides all wiring and functions as a discreet black box. This is achieved by enclosing all system components within the box illustrated below.

The box is easily accessible, facilitating the replacement of components or even reprogramming of the system when necessary. Within the plants care station, the central orchestrator is the Arduino Nano, functioning as the main brain to coordinate all other components. Accompanying this, a DS1302 module is integrated to manage real-time control, influencing watering decisions. It considers optimal watering times, favoring mornings and evenings when sunlight is less intense, promoting better absorption and utilization of water by the plants. This thoughtful scheduling enhances the overall efficiency and well-being of the plants.

Power supply

For the entire system, a 9V battery serves as the power supply. It separately powers both the Arduino and the water pump. Considering that our water pump operates on 5V, we require a voltage transformer. For this purpose, we have used the AMS117 module.

In contrast, the DS1302 operates on a separate CR2032 battery, ensuring a dedicated power source to sustain the Real-Time Clock (RTC) functionality. This dual-power configuration enhances the efficiency and autonomy of each component, ensuring the overall reliability of the system.

Control elements

The plants care station comes equipped with some handy controls like LEDs, buttons, and a potentiometer to enhance its overall functionality. A straightforward on/off switch simplifies the activation of the station. When manual watering is needed, a dedicated push button is readily available. Additionally, the potentiometer allows for accurate adjustment of the water amount during automatic mode.

These user-friendly controls provide a precise and efficient means of managing your plant care routine.

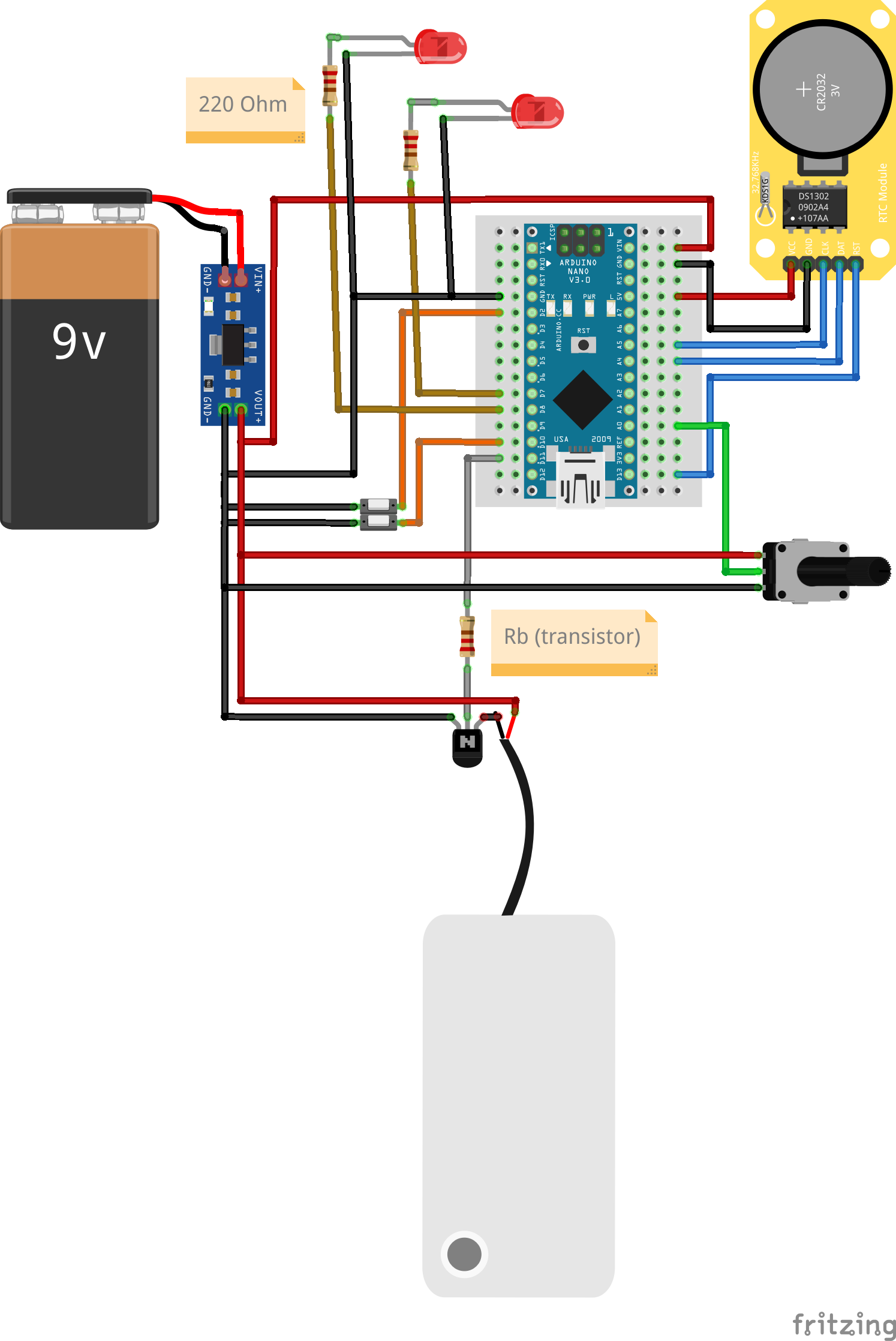

Wiring schema

Creating a precise wiring schema is essential for the optimal performance of the automatic watering system. This schema serves as a practical guide, interconnecting main components. Methodically organizing and routing the wires prevents potential confusion during the assembly process. Clarity in both assembly and troubleshooting phases is achieved through the implementation of color-coded distinctions and strictly following specified pin configurations for facilitating the communication between modules.

The above wiring schema offers a comprehensive overview of the system wiring and connections.

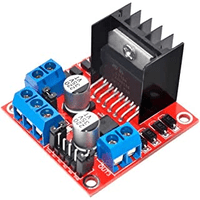

Calculating base resistor value

In order to compute the base resistor (RB), we must first determine the collector current. Given that the circuit's sole load is the water pump, it can be deduced that the collector current is identical to that of the water pump. Based on the water pump specification, we know that IC = 200 mA, or for practical purposes, IC = 0.2 A. This forms the basis for our calculations.

It is important to note that if we exceed the parameters for which the transistor was designed, it will eventually burn out. With this in mind, we will proceed to identify the transistor's gain from the datasheet. We observe that when IC = 200 mA, its gain is 100. We have now discovered our second value: 𝛽 = 100.

Once we've established the gain, our next step is to calculate the base current. It's important to recognize that the collector current is directly proportional to the base current and the gain. This relationship can be expressed mathematically as:

hFe = 𝛽 (gain) = Ic / Ib

Replacing the values, we acquire our third parameter: Ib = 2mA = 0.002A. Now, we can compute Rb value using Ohm's formula:

Vb = VS - VBE = Ib * Rb

Rb = (VS - VBE) / Ib

Where VS is the source voltage, and VBE is the voltage drop across the base-emitter junction of the transistor. In our circuit, the transistor's base is connected to an output from an Arduino. An Arduino output provides a maximum of 5V and 40mA. Therefore, we have a source voltage of 5V, and the transistor's barrier potential is 0.6V.

Rb = (5V - 0.6V) / 2mA = 2.2kΩ

For our circuit, the suitable value for the base resistor should be equal or below 2.2K ohms. We choose the lower standardized resistor and check by looking at the datasheet curves that the base voltage is sufficient to drive the transistor into saturation.

Automated plants watering system

After going through rounds of mounting and wiring adjustments, we're excited to introduce our initial prototype of the automatic watering system. Check out the results and get a general overview of the system in the attached image below. We're really looking forward to seeing how well it takes care of the plants and are ready to make it even better by identifying areas for improvement.

The internal components of the plant care station neatly fit into the box, presenting a clean and user-friendly appearance. The next step involves experimenting and testing the system over some time to identify any weaknesses and enhance its performance. Additionally, we aim to minimize its size and simplify the wiring, making maintenance more straightforward.

Conclusion

In wrapping up our journey through the practical implementation of an Arduino-powered automatic watering system, you've navigated the intricacies of physical mounting, sensor integration, and module connections. What started as abstract concepts has materialized into a self-built, technology-infused plant care solution. In the upcoming article, we'll explore the necessary code to implement these circuits and activate our system.

0 Comments